Rollaway Nest Box System for Eggmobiles Explained (How It Works + What You Need)

Share

If you’ve ever run an eggmobile on pasture, you already know the truth: the “nest box problem” isn’t just about giving hens a place to lay.

It’s about keeping eggs clean, collecting fast, and making sure the whole setup still works after you move the coop onto uneven ground.

In this post, we’ll explain how our Rollaway Nest Box System works, why we designed it specifically for eggmobiles, and what you need to plan before installing it.

Quick answers

How do rollaway nest boxes work?

We set the nest floors at a slight slope so eggs roll away by gravity into a protected collection area—out of reach of hens.

Why does leveling matter in eggmobiles?

Eggmobiles move across uneven pasture. If the conveyor isn’t level and the floors aren’t at the intended angle, rollaway + conveyor collection won’t work as smoothly.

Is this a DIY kit?

Yes. We ship it as a flat-pack DIY kit on two Euro pallets, and we provide personal guidance and video instructions for assembly.

What this system is (in one sentence)

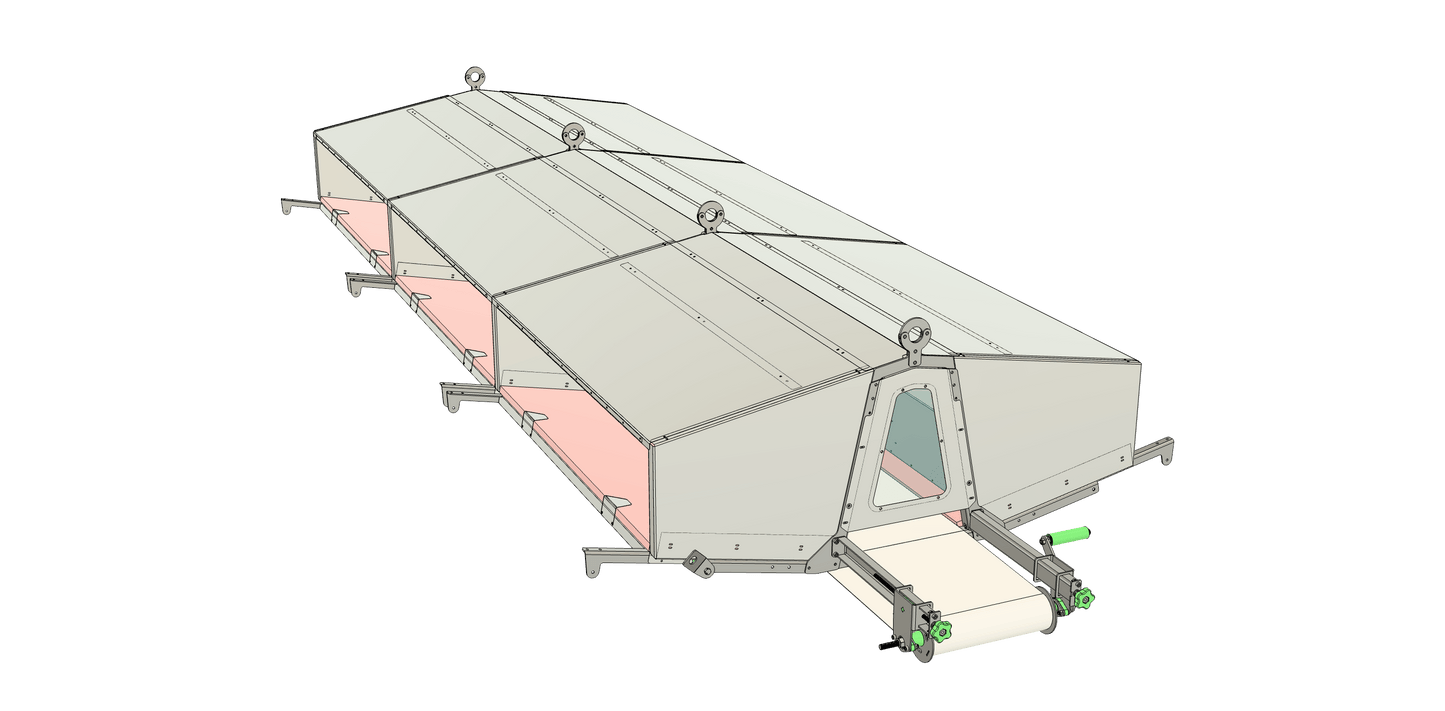

It’s a two-sided rollaway nest box system with a central conveyor belt, designed to stay functional in an eggmobile that moves across pasture.

How it works: rollaway floors + central conveyor

We kept the core mechanism simple and practical:

- Two-sided nesting: nests on both sides, with a conveyor belt running down the center.

- Slanted nest floors: the nest floors are slightly slanted (12°) so each egg rolls away by gravity.

- Protected egg collection: eggs roll out of reach and into the protected collection area, then the conveyor brings them to your collection point.

The goal is straightforward: cleaner eggs, smoother collection, and less time wasted walking and searching.

The “eggmobile problem”: leveling on uneven pasture

Most nest boxes are designed for coops that sit on a flat floor. Eggmobiles don’t live on flat floors.

After each move, the ground slope and frame twist can change slightly—so the conveyor needs to be flat and the nest floors need to stay at the intended angle.

That’s why we designed the structure to be suspended and able to tilt below a pivot point. It lets you re-level the nest box system more easily after moves.

Keeping nests clean: tilting floors

One feature we’re especially proud of is the tilting floors.

- Night lockout: we can tilt the floors to exclude hens from the nest boxes at night, which helps keep nests clean.

- “Self-cleaning” action: the daily tilt motion helps loose dirt, feathers, and droppings fall off the mats and onto the floor.

Reality check: if an egg breaks, residue can stick to the nest pad and you’ll need to remove it manually. Loose debris tends to come off naturally and easily.

Modular sizing: segments, nest area, and total length

We sell the system in 120 cm segments. Each segment provides exactly 1 m² of nest floor area.

Compliance note: we recommend checking your local regulations to size the total nesting area required for your flock.

Total length by segment count

| Segments | Total length (mm) | Total length (m) |

|---|---|---|

| 2 | 2793 | 2.793 |

| 3 | 3902 | 3.902 |

| 4 | 5011 | 5.011 |

| 5 | 6120 | 6.120 |

| 6 | 7229 | 7.229 |

DIY kit: what’s included vs what you supply

Flat-pack shipping: we ship the system as a flat-pack kit on two Euro pallets, and we provide clear video instructions for assembly.

What’s included

- All metal and plastic components for the frame and mechanism

- Nest mats and internal flooring

- Conveyor belt system for egg collection

- Hardware and fasteners for assembly

- Red tarp flaps for shading the nesting space

- Step-by-step video instructions

What’s not included (what you supply)

- Pivot tube: Ø 33.7 × 3 mm steel tube (galvanized or painted)

- Wooden perches: approx. 5 × 3 cm battens (they connect all floors so they move in unison)

- Electronics (optional): actuators, timers, and control electronics (your choice, depending on your setup)

Automation + power options (context-based)

We designed the system so it can be automated, but we didn’t want to force one electronics package on every farm. The best setup depends on your eggmobile and your power strategy.

Here are power options we commonly discuss with customers:

- Solar system (12V or 24V)

- Cordless drill battery (charged and swapped as needed)

- E-bike battery with a step-down converter

Design tips for eggmobiles (so service access stays easy)

If you’re building a new eggmobile—or planning a major upgrade—roof geometry matters.

- Recommended: a gable roof with two sloping sides meeting at a ridge (easiest install and maintenance access).

- Can work: one-sided (Ridgedale-style) roofs, but space is tighter and service access is more limited.

Retrofit checklist (before you order)

- Measure space + service access: make sure you can comfortably install and maintain the system in your eggmobile.

- Plan for leveling: eggmobiles move—plan how you’ll re-level after each move.

- Prepare for sourcing: pivot tube + wooden perches are standard parts you’ll source locally.

- Decide your automation level: manual vs automated tilting floors, depending on your context.

- Choose segment count: use 1 m² per segment + your local nesting-area requirements + the length table above.

FAQ

Is this only for eggmobiles?

We designed it specifically for eggmobiles, but it can also be installed in stationary coops.

Why 12° on the nest floors?

We use a 12° slant so eggs roll reliably down by gravity onto the conveyor belt and out of reach of hens.

Do we need automation to use it?

No. The system can be automated, but actuators/timers/electronics are optional and depend on your preferred setup.

What do we absolutely need to source locally?

The pivot tube and wooden perches are not included. If you want automation, you’ll also source actuators/timers/control electronics.

Why isn’t the pivot tube included?

We designed the kit to ship efficiently on Euro pallets, so we can’t ship long parts. The tube is a standard part that’s easy to source locally.

How “self-cleaning” is it?

The daily tilting motion helps loose dirt, feathers, and droppings fall off the mats. If an egg breaks, residue can stick and requires manual cleaning.

How do we decide how many segments we need?

Each segment provides exactly 1 m² of nest floor area. Use your local nesting-area requirements and then check total length from the segment table.

How hard is assembly?

It’s a flat-pack DIY kit designed to be assembled with the provided video instructions by non-skilled or moderately skilled people.

Next step

If you want photos, lead time, and current pricing, visit the product page:

Rollaway Nest Box System for Eggmobiles

If you’re retrofitting into an existing eggmobile and want help thinking through the cleanest solution for your context, contact us—we’ll support you in working out the best setup for your farm.